PLA Food Packaging: Everything you need to know(2023 Update)

- By YANXIYAN

- May 24, 2023

Today, I’m going to share everything that you need to know about PLA food packaging

In this article, you will learn:

- What is Polylactic acid (PLA)

- What is the manufacturing process of PLA

- Is PLA plastic food packaging safe?

- Advantages of PLA food packaging

- Disadvantages of PLA food packaging

- Environmental benefits of PLA food packaging

- Applications of PLA in food packaging

- Tips for storing PLA food packaging safely

Let’s dive in

What is PLA?

PLA is short for Polylactic acid. It is a thermoplastic filament derived from natural, renewable sources like corn starch or sugar cane.

First discovered by Wallace Corothers, the inventor of Nylon, in the 1920s, PLA was not initially used commercially.

However, by 2010, it became the second most valuable bioplastic in the packaging market based on consumption figures.

PLA is sometimes called “corn plastic.”

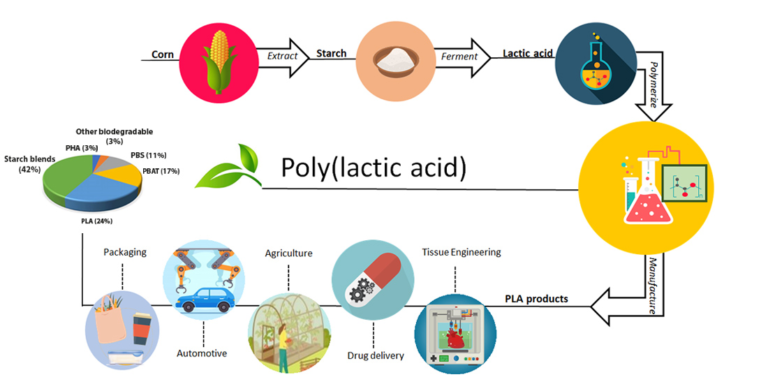

What Is The PLA Manufacturing Process?

PLA, or polylactic acid, is a bioplastic made from renewable resources like cornstarch or sugarcane.

The manufacturing process for PLA involves several steps, including fermentation, separation, purification, and polymerization.

During fermentation, microorganisms break down the starches in corn or sugarcane into simple sugars.

These sugars are then separated and purified before being transformed into lactic acid through polymerization.

Finally, the lactic acid is polymerized and converted into PLA resin pellets, which can produce various products, including food packaging, disposable utensils, and 3D printing filaments.

Is PLA Food Safe?

Yes, PLA plastic is generally considered food safe.

Studies have shown that PLA containers used for food packaging showed no significant evidence of harmful substances transferring into the food.

Furthermore, PLA is an FDA-approved Generally Recognized Safe (GRAS) polymer when used in contact with food.

PLA is the most commonly used bioplastic in the food packaging industry

However, it’s important to note that the safety of PLA may vary depending on the manufacturing process, additives used, and other factors.

For example: Heating PLA filament produces a hazardous chemical called methyl methacrylate.

Another point to consider is that while PLA can withstand temperatures up to 110 degrees Fahrenheit, still it’s not recommended for hot foods.

Note: Always remember to check the specific guidelines and recommendations for using PLA products and choose a reputable manufacturer to ensure the safety and quality of the product.

Advantages of PLA in Food Packaging

PLA has four main advantages that make it a popular choice for food packaging in following

High Transparency

PLA is an explicit and transparent material, just like PET, making it an ideal food packaging option.

One of the most significant advantages is that you can see the contents without opening the package.

For example, PLA is widely used for clear food packaging, like fruits, salads etc.

A study found that transparent PLA packaging did not affect the quality and safety of sliced ham stored in the packaging. This study confirms that PLA is a safe and effective material for transparent food packaging.

Keeps Food Fresh

PLA has excellent oxygen and water barrier properties, which help to preserve the freshness and quality of food

For example, Studies have shown that PLA-based packaging films can extend the shelf life of fruits and vegetables by up to two days compared to traditional plastic packaging.

Food stored in PLA food packaging has been tested to maintain its flavour and taste for up to a week.

In comparison, other packaging materials, namely PET, have kept the food’s flavour for only three days.

Biodegradability

PLA is an eco-friendly alternative to traditional plastics that can take years to decompose.

While PLA is biodegradable and compostable, a Wageningen Food & Biobased Research study found that compostable products made with PLA disintegrated faster than orange peels or paper.

The study showed that the PLA-based products couldn’t be recovered even after one composting cycle of 11 days, raising questions about their effectiveness in reducing waste.

It’s important to note that the biodegradability and compostability of PLA may vary depending on the conditions of composting facilities and other factors.

Non-Toxic

PLA food packaging does not release any toxic gasses that can harm humans.

As it is made from natural sources, PLA is completely carbon neutral and 100% renewable.

The non-toxic property of PLA is also great in improving the food safety of PLA-coated paper food packaging materials.

PLA won’t release harmful chemical material as petroleum-based products

Disadvantages of PLA in Food Packaging

PLA also have four disadvantages as a food packaging material; let’s explore

Low-temperature resistance

PLA has a lower temperature resistance than traditional plastics, with a maximum recommended use temperature of around 110°F (43°C).

In contrast, conventional plastics such as polypropylene can typically withstand temperatures up to 220°F (104°C).

This makes PLA unsuitable for hot foods or liquids and not recommended for packaging hot soups or beverages.

Higher cost than other plastic materials

PLA is generally more expensive than PET or PP.

The main reason for the higher cost of PLA is its extensive production process involving several chemical treatments needed to get PLA out of cornstarch.

Unless researchers can find ways to simplify the PLA production process, the PLA’s higher price tag will continue.

Recyclable Problem (Is PLA Recyclable?)

Yes, technically, PLA is recyclable.

However, due to the lower melting point of PLA, it can not be recycled with other plastics.

This can cause contamination and damage to the recycling machinery.

And PLA mixed with traditional plastics reduces the recycled material’s quality and durability.

Despite these challenges, there are still ways to recycle PLA.

The two main methods are to hand it over to a recycling plant that knows how to handle it or to grind it up and extrude it into new filament.

However, both methods require specific equipment and processes, making them less accessible and more costly than traditional plastic recycling.

Need for specific conditions to decompose

PLA needs to be composted in industrial facilities with controlled conditions, which can limit its biodegradability in particular settings.

If you don’t provide these conditions and leave them be, it may take up to 100 years for PLA packaging to decompose.

For PLA to decompose efficiently, it requires specific conditions, such as a temperature between 122-140°F (50-60°C), moisture, and oxygen.

Industrial composting facilities have these conditions to ensure PLA can break down within 90-180 days.

Environmental Benefits of PLA Food Packaging

PLA has several environmental benefits that make it a sustainable and eco-friendly option for food packaging. Here are some key points to consider:

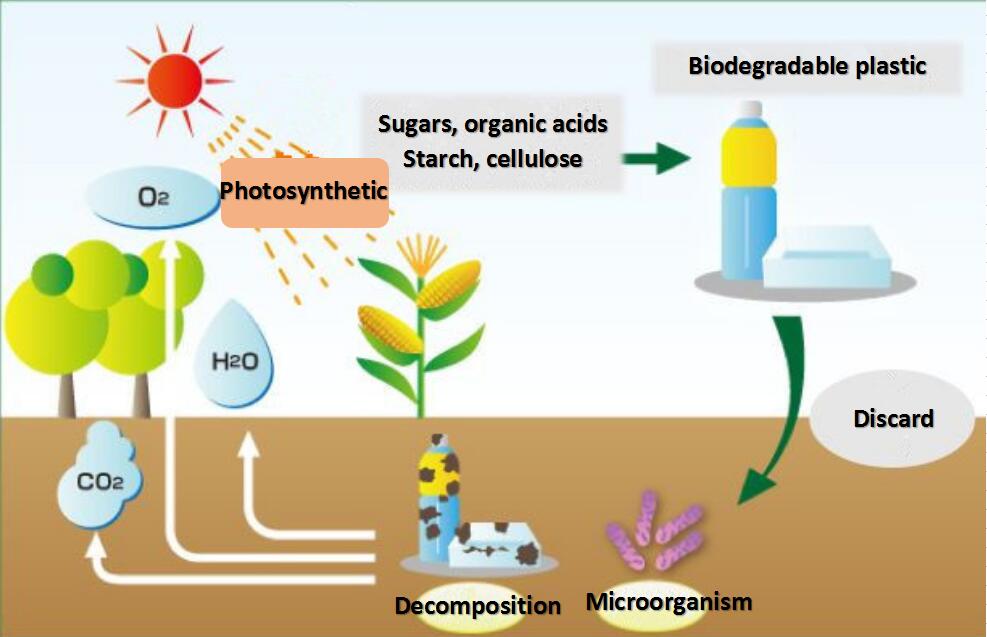

Made from renewable resources

PLA is made from renewable resources like cornstarch or sugarcane, reducing our dependency on fossil fuels and non-renewable resources.

For example, PLA production could reduce greenhouse gas emissions by up to 50% to 75%

Moreover,The production of PLA decrease fossil fuel consumption by up to 65% compared to traditional petroleum-based plastics.

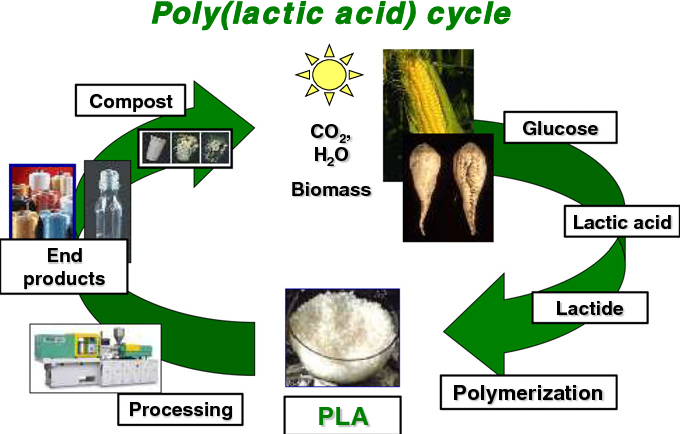

Biodegradability and Composability

PLA is biodegradable and compostable, which means microorganisms in industrial composting facilities can break it down.

It is far much better than traditional plasitic which are able to be biodegradable

PLA can fully degrade into natural elements like water, carbon dioxide, and organic matter in just a few months.

This reduces its environmental impact and prevents it from ending up in landfills or oceans.

PLA can take between 6 months to 2 years to decompose in industrial composting facilities, depending on the conditions.

However,The time taken for PLA to biodegrade in the wild is at least 80 years. This is because, without the specific conditions needed, PLA can’t biodegrade in nature

Reduced Greenhouse Gas Emissions

The production of PLA generates fewer greenhouse gas emissions than traditional plastics.

This is because the production process for PLA uses less energy and produces fewer emissions.

For example, producing PLA requires 65% less energy than traditional plastics and releases 68% fewer greenhouse gases, making it a more sustainable choice for the environment.

Applications of PLA in Food Packaging

PLA is a versatile material used in various food packaging applications. Here are some common applications of PLA in food packaging:

Disposable PLA containers

PLA containers are a popular choice for takeout and delivery of food packaging due to their durability and versatility.

PLA disposable containers are great for keeping your food fresh for a long time when stored correctly.

For example, McDonald’s fast-food chain has started using PLA containers for its McFlurry desserts and salads

According to a report by Grand View Research, the global PLA market for food packaging is expected to reach USD 2,772.93 million by 2030, driven by the increasing demand for sustainable and eco-friendly packaging solutions.

TIPS:PLA container is advised against storing very hot food

PLA utensils

PLA utensils like forks, spoons, and knives are a sustainable alternative to traditional plastic utensils, significantly contributing to plastic waste.

Tableware or utensils manufactured from PLA are sturdy and can be used more than once

For example, the food service company Aramark has replaced over 2 billion plastic utensils with PLA utensils in its colleges and universities across global operations.

PLA utensils are also completely food safe and can be recycled or composted when discarded.

PLA straws

PLA straws are a biodegradable alternative to the plastic straw problem, which is a major contributor to ocean pollution

These straws are much more eco-friendly and have a very little carbon footprint as compared to plastic straws

More and more people will choose PLA straws compared to plastic straw

According to a report by Technavio, the global market for PLA straws is expected to grow by $1.22 billion during 2022-2026, accelerating at a CAGR of over 22.6%.

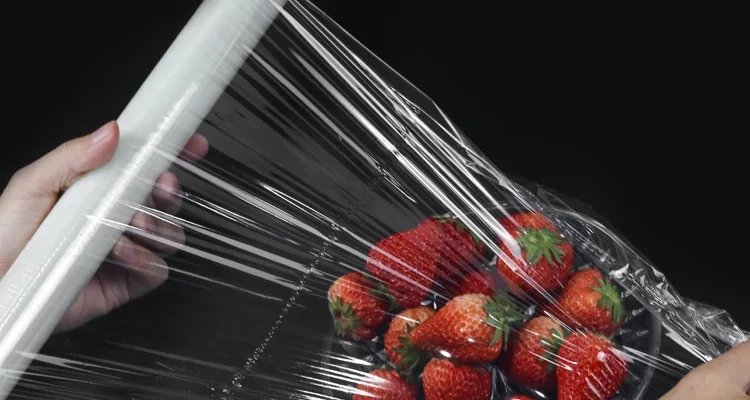

PLA film for food packaging

PLA film is a clear, biodegradable laminating film that packages food products like meats, cheeses, and snacks

It also creates a barrier for odour which helps you keep your food fresh inside the packaging.

For example, the UK supermarket chain Tesco has switched to using PLA film for its meat and poultry products.

According to a study, PLA film can potentially reduce greenhouse gas emissions compared to traditional petroleum-based films

PLA Coating Paper

PLA coating paper is used to produce paper cups, bowls, lids, and boxes, providing a barrier between the food and the paper and preventing leaks and spills.

PLA can be coated on Kraft paper, white paper, or bamboo paper.

The PLA-coated paper container is very versatile and can be used to store hot or cold food items without any problems.

For example, the coffeehouse chain Starbucks has introduced PLA coating paper in its cups to reduce its environmental impact.

PLA Foam Clamshells

PLA foam clamshells are a popular choice for fast-food packaging due to their lightweight and durable nature.

These clamshell products are great for storing both cold and hot food items

PLA creates a hydrophobic surface, condensation from the food does not impact the structural strength of the packaging in any way.

For example, the fast-food chain Burger King has started using PLA foam clamshells for its Whopper sandwiches.

How to Store PLA Food Packaging?

Proper storage of PLA food packaging is essential to maintain its quality and extend its shelf life. Here are a few key points to consider when storing PLA food packaging:

- Keep it in a cool, dry place: Store PLA in a cool and dry location to prevent moisture from affecting its biodegradability. Moisture can cause PLA to degrade and break down more quickly than intended.

- Avoid direct sunlight and heat: Direct sunlight and heat can cause PLA to break down and degrade faster. Keep PLA away from windows and heat sources to maintain the right temperature and prevent it from melting

- Store it for a short time: While PLA has a longer shelf life than other biodegradable plastics, use it within a reasonable timeframe to prevent it from degrading before use. PLA food packaging is recommended within six months to a year of purchase

- Store it in airtight containers: Air exposure can cause PLA to degrade faster. To keep it fresh, store PLA in airtight containers or packaging

- Don’t expose it to chemicals: PLA can be affected by chemicals. Avoid storing it near cleaning supplies, solvents, or any other chemicals that could potentially come into contact with it.

Conclusion

What did you think of this article?

Have you used PLA food packaging before?

Let me know in the comments below.

It’s time to positively impact the environment and promote sustainability through our choices.

One Response

Wow, very well written. Extremely comprehensive. Well done!