The Complete Guide:Everything You should know about Offset Printing

Offset printing or offset lithography is one of the most popular printing methods that generate consistent and high-quality printed result. It is a widely used commercial printing method and has been around since the 20th century. It can produce large volume, high-quality prints and labeling packages such as cartons and boxes.

Despite being an old process, it outweighs other printing options in certain situations. For instance, offset printing produces larger quantities of high-quality prints cost-effectively than digital printing. But how does it work, and why is it the best choice for your production business? Find out more

What is Offset Printing?

Offset lithography is a printing method that transfers ink from a plate to a rubber sheet (or blanket) and then to the substrate. This printing process is “offset” because the inked image isn’t transferred directly onto the printed substrate as other printing methods do. Instead, the ink is first transferred to a rubber cylinder before it is delivered ink to the paper. The three-step process helps to reduce the wear and tear of the printing plate, hence extending its lifespan.

How it works?

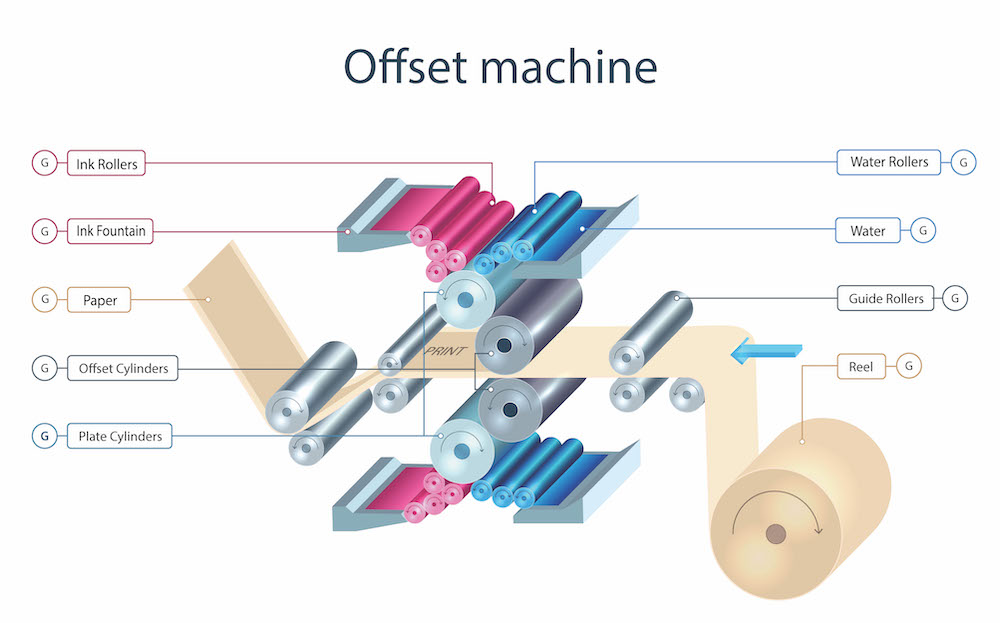

The offset printer includes three cylinders/rollers; impression cylinder, plate cylinder, and blanket cylinder. The offset printing press utilizes these rollers to deliver ink to the paper

The plate cylinder has plastic or aluminum printing plates designed specifically for each print task. The plates comprise images transferred to the paper. And The plate is treated so that the image areas attract ink and non-image areas attract a water solution that repels ink.

As the plate roller spins, water solution distributes itself onto the plate, and ink is dispersed onto the plate. Hence, the ink sticks to the image areas while the water solution drives away ink from the non-image areas.

The blanket cylinder has a rubber blanket around it and turns in the opposite direction of the plate cylinder. As the plate cylinder rolls against the blanket cylinder, the water on the plate is repelled, and the ink is transferred to the rubber blanket.

This process creates a reversed image of the ink design to be printed.

The impression cylinder is made of clean steel and turns in the opposite direction of the blanket cylinder. It compresses the paper against the rubber blanket to transfer ink to the paper. As a result, the image on the paper symbolizes the exact picture on the plate.

This explains why this method of printing is referred to as offset printing. The image is not transferred directly onto the paper. Instead, it’s offset to a middle roller before being applied to the paper.

This method is commonly used for mass production, such as printing longer runs of newspapers, posters, magazines, brochures, books, letterhead, and manuals.

Offset printing presses can print up to 18,000 sheets per hour, with each sheet containing up to 48 pages of A4. One offset press can print eight pages per sheet, totaling around 120 000 pages per hour! Offset printing is a fast and efficient method for printing.

The Offset Printing Process: Step By Step

The offset printing process follows the same cycle from start to finish.

- Design

An excellent printing job starts with a great artwork design. Here, we can decide the coatings, color, font, paper type, and layout. Then, once the print material specifications are known, get the estimate.

- Pre-Press

With the digital art file made into a proof, showing what the final printed piece will look like, it’s time to review the evidence. Most warranties are sent to the client in PDF form, sometimes called soft proof. You can make changes if any

- Platemaking

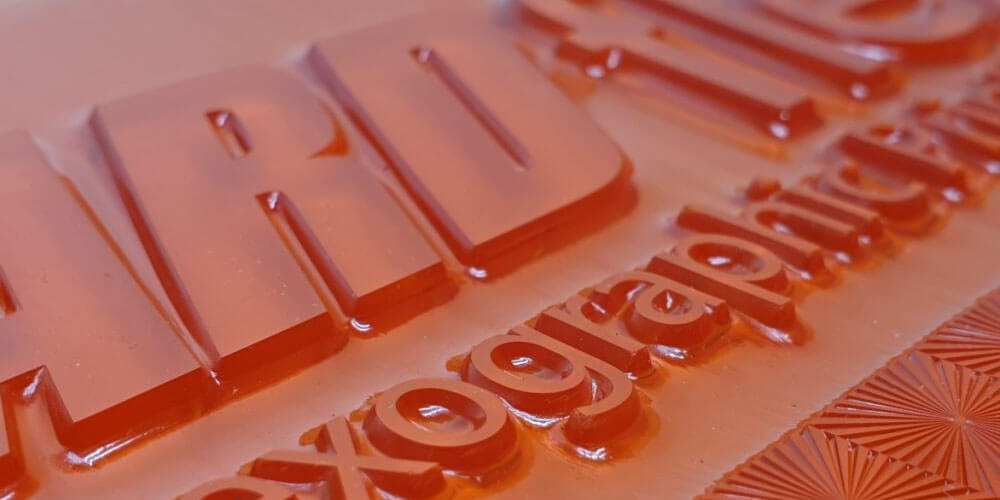

The computer-to-plate system uses digitally controlled laser engraving systems to directly take digital files and images to aluminum plates. It results in high-quality, accurate printing. The plates are then fixed onto a roller, one for each color.

- Wetting

Plates are first passed through wet rollers before they are exposed to ink. The water and additives solution flow continuously, wetting the entire plate. Since the plates are treated, they resist water where the color needs to be printed.

- Inking

The ink roller applies oil-based ink to the plate using special vibrating rollers, ensuring even ink distribution. Once the ink roller comes into contact with the wet plate, the ink sticks to the untreated parts of the plate.

- Offsetting

The rubber roller lifts the ink off the plate, creating a reversed image on the roller’s surface. The roller is flexible enough, allowing it to be used with different papers, including rough, textured, and glossy.

- Printing

In this final step, the printed materials are folded, trimmed, perforated, collated, bound, etc., to match the specifications of the final product. It may also include adding matt laminations or gloss to the printed paper.

- Finishing

An excellent printing job starts with a great artwork design. Here, we can decide the coatings, color, font, paper type, and layout. Then, once the print material specifications are known, get the estimate.

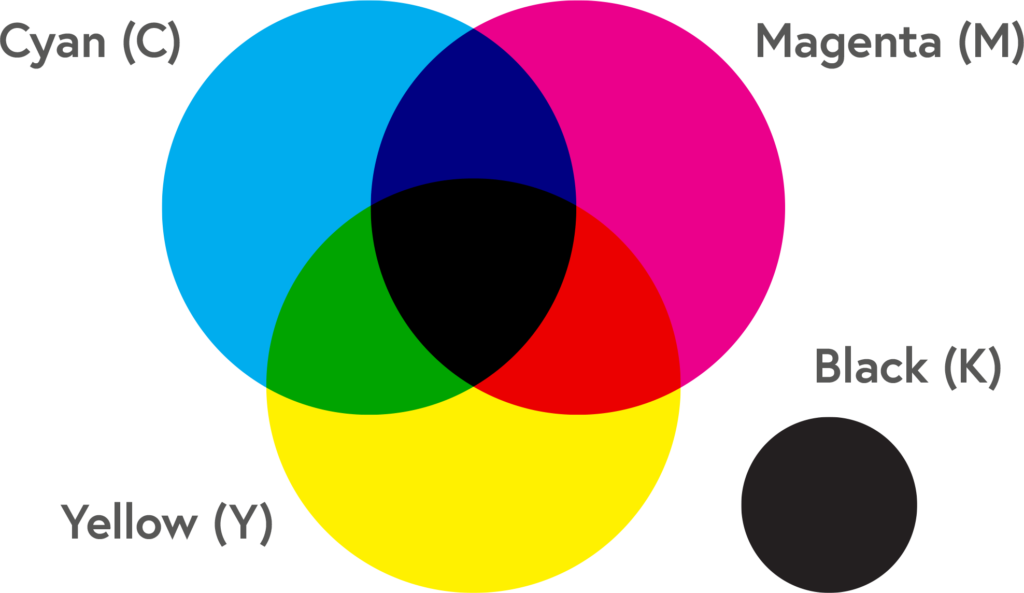

What is 4-color offset printing?

Four-color offset printing means four ink colors are used in offset printing presses and various digital presses. These four colors include Cyan, Magenta, Yellow, and Black (CMYK). They are combined to make multiple colors.

CMYK printing is also called Full-Color printing, 4CP, Process Printing, or four-color printing

Most, if not all, commercial printers use the 4CP method for projects that contain multi-colored designs or images, including books, magazines, postcards, and manuals, among other printed items with full-color photos.

Full-color photos are created by applying separate layers of the four inks. When these four colors are overlapped in distinct concentrations, the designer can reproduce thousands of colors.

An offset press utilized for the 4-color printing process has four sets of rollers, one for each color. RGB (red, green, blue) is another color combination used in digital images and monitors.

To achieve optimal reproduction of your digital photos, use RGB, a default setting for most photo-editing software

What type of ink is used in offset printing?

Oil-based ink is a specific type of offset printing ink used in offset printing presses. This ink must be able to resist water-ink-emulsification and other chemicals it will come into contact with on the press.

Ideally, the ink should not break down or combine with the fountain solution on the non-printing areas of the engraved plate (ink-in-water emulsification).

These emulsification problems impair the color and drying qualities of the ink, resulting in tinting on the printed sheets and non-printing areas of the plate.

Oil-based ink comprises three main ingredients; pigment, vehicle, and modifiers. The pigment is the coloring material of the ink, while the vehicle is the liquid that holds pigment particles and carries them to the paper.

On the other hand, modifiers are ingredients added to the ink to control the drying of the ink and other factors such as fading, smell, resistance, and scuff

Today, most Oil-based ink have shifted from using petroleum-based ink to a soy-based product that is more reliable and environmentally friendly.

And it also provides precise color and makes it easier to recycle paper as it is easily removed in the de-inking process.

It’s, however, not biodegradable since it contains acrylate, styrene, and iron oxide, which cannot be broken down. In addition, compared to other inks (water-based ink), it dries slowly

What is offset printing used for?

Offset printing is typically used for continuous production, such as printing large quantities of magazines, newspapers, brochures, and stationaries. It is one of the most used printing techniques for its high-quality precision and output.

Additionally, offset printing is used to print high-quality promotional materials such as product advertisers and branded coasters.

It’s the best option for people looking for rich colors and highly detailed imagery. It is also an effective method for printing plastic menus, tent cards, and hotel over door hangers.

Generally, it’s an excellent option for high-quality and more significant projects at a limited budget. It’s a simple way of printing a continuous, repeating message on moving products like pipes and metal bars.

Moreover, most companies use the offset printing method to print business cards that help to build brand awareness. Schools have also utilized this printing method to produce large volumes of stationery and reading materials.

Benefits of offset printing?

- High-definition quality: Expect high-quality printed images when using the offset printing process for your business. With the printer operator controlling the ink flow, fewer wasted prints will lead to clean, sharp images on every piece.

- Print on any surface, material, or shape: the flexibility of the rubber blanket used in the offset printing process makes it easy to print on different textures and shapes. You can print on plastic bottles, round containers, or print labels without a hassle. With Offset printing, you can also print on various materials such as metal, wood, fabric, and different paper grades.

- Low cost and faster printing: One of the most significant advantages of offset lithography is the cheaper cost of high-quality prints. The more pieces you need to be printed, the less it costs to produce each piece. In addition, in offset printing, the printer operator can control the ink flow to ensure that your print quality remains at a maximum output level. Hence, your print job is less likely to be interrupted, which means large quantities in less time.

- Less costly printing plates: Each print job requires a customized printing plate for every project, which can be expensive. But, thanks to technology, the plates are easy to make, less expensive, and can be used multiple times, which helps keep costs low.

Disadvantages of offset printing

- Requires extra setup time because the offset process includes the added steps of creating plates and performing the transfer

- Offset lithography makes personalization more difficult. For projects requiring customized pieces such as letters and postcards, digital printing will more likely provide the flexibility you need.

- The extra time spent on the initial setup process is expensive, especially if few copies are needed. For low-quantity print jobs, offset printing is costly and time-consuming

- The printing plates are made of anodized aluminum, making them prone to chemical oxidation. Thus, they may require extra care and maintenance.

- You will need skilled operators to keep the quality at the expected level because the offset printing process is complex

Offset Printing VS Flexographic Printing

While both offset and flexographic printing use the same printing process of plates and wet ink, there are substantial differences between them. They differ in the following factors;

Plates

As the name “Flexo” suggests, flexo printing utilizes flexible plates for the printing process. These plates are made from a photopolymer compound which enables them to wrap around a printing cylinder.

A separate printing station and flexo plate are required for each color. The image is then printed straight onto the substrate. The printing plates are durable and, if stored correctly, can be reused several times before they can be replaced.

For offset printing, ink is transferred via rollers onto the printing plate. It can be either a rotary process or flatbed, depending on the type of offset press. The plate is made of aluminum. Before drying, the complete wet image is transferred to a blanket and then onto the substrate.

Although they all need to make plate for printing, The flexo printing photopolymer plate is much more expensive than offset aluminum printing template.

Ink

Offset printing consists of four process colors: cyan, magenta, yellow and black. Each color has its printing station. In addition, offset printing supports many inks, including oil-based or UV curable and metallic inks.

Flexo printing can operate with UV curable or water-based inks and solvent-based inks. UV inks facilitate higher running speeds and can be left in the press after printing; thus, no need to empty and clean each print station.

Water-based inks need to be removed from the machine when not in use to prevent ink from drying in the ink trays and on the rollers.

Process colors can also be used in the flexo process, but additional print stations are usually used for spot colors. Spot colors can be supplied pre-mixed or mixed in-house, as required

Offset printing mainly uses oil-based ink, but it will take a long time to dry. Flexo printing mainly uses water-based ink which will dry quickly

Suitable Printing Materials and Products

This is the most significant difference between flexographic and offset printing.

Offset printing machines print on different materials such as metal, vinyl, cardboard, and paper, provided the surface is flat and smooth. This makes offset printing an ideal printing method for producing items such as books, posters, magazines, and brochures.

Flexographic printing can be used on various materials and printed on any substrate with a flexible surface, such as fabric, plastics, and foil. It is mainly used for packaging; sweet wrappers, retail bags, wallpaper, label stock, and wrappers.

Flexography can achieve high-speed production and good color quality. It can also be used on absorbent and non-absorbent materials such as paper, aluminum foil, paper board, PET, and BOPP.

When choosing between offset and flexo printing methods, it’s essential to consider certain factors, including your preferred substrate and project requirements.

While both printing methods are versatile and practical, each has different advantages and disadvantages.

The main difference between both printing processes is that offset printing can only be done on a flat surface. In contrast, flexographic printing can be done on any substrate with a flexible cover.

To sum-up

When choosing the correct printing technique for printing marketing materials, it’s vital to consider a few factors such as quantity, budget, and production speed. For example, offset printing is a popular method used across various industries. Besides providing high-quality output and consistent results, it adds value to packaging, products, or publications.

If you need a large batch quickly, offset lithography is one of the best options for fast-around time. Unlike digital printers, offset printers are cost-effective and more efficient. Offset printing outweighs all other methods based on functionality, versatility, and cost-efficiency.

About Us

YANXIYAN is a 10 years foodservice packaging expert. If you are looking for a professional packaging solution and advice, Just message us.

Recent Posts

Related content

Full Guide to the Types of Paper Bags(2023)

Full Guide to the Types of Paper Bags(2023) With its biodegradable and eco-friendly characteristics, paper bags contribute to the sustainability of the environment. Today we

17 Best Types of Eco-Friendly food packaging in 2023

17 Best Types of Eco-Friendly food packaging in 2023 Today, I will dive into the fascinating world of eco-friendly food packaging. As sustainability and environmental

The Ultimate Guide To types of ice cream packaging (2023)

The Ultimate Guide To types of ice cream packaging (2023) Ready to dive into the sweet world of ice cream packaging? Today, In this guide,

Can You Recycle Ice Cream Cartons?

Can You Recycle Ice Cream Cartons? In this article, I will share valuable information about ice cream carton recycling, including common types of materials used

The Ultimate Guide To Food Delivery Packaging in 2023

The Ultimate Guide To Food Delivery Packaging in 2023 Today I will show you everything you need to know about food delivery packaging. In this

Best Disposable Bowl for Hot Soup:All You Need To Know (2023 Update)

Best Disposable Bowl for Hot Soup:All You Need To Know (2023 Update) What is the best disposable bowl for hot soup? In this article, you

3 Responses

Itís nearly impossible to find well-informed people for this topic, but you seem like you know what youíre talking about! Thanks

Can you plz suggest how much time printing ink take to dry on for paper.

Hi there all, here every person is sharing such knowledge, so it’s

good to reazd this website, and I used tto go to see this webpage all the time.