What is PLA Coated Paper ?(Everything you need to know)

The world is slowly but surely trying to turn away from plastic packaging for more eco-friendly packaging options. As a result, many customers have started to choose paper packaging as a new alternative.

But there is a catch. Most paper packaging needs to be coated with a plastic layer to be liquid-resistant.

Even though plastic does its job well, it makes paper harder to decompose, causing landfills to fill up quickly with waste. PLA coated paper is the solution to all the problems posed by plastic coated paper

What is PLA coated paper, and how is it solving all the problems of paper packaging? Let’s find out.

What Is PLA Coated Paper?

PLA coated paper is food-grade paper coated with a PLA film layer to create a hydrophobic (water-resistant) surface resistant to liquid. PLA coated paper is one alternative to plastic food packaging.

In addition, PLA coating paper can apply it to a different disposable container made out of paper. So why do we suddenly shift to PLA lining paper? Let’s find it out.

Why Should We Choose PLA Coated Paper?

Eco-friendly benefit

Paper containers, especially cups, were typically coated/lined with plastic or polyethylene (PE). Plastic is not biodegradable and is harmful to the environment. PLA does the same job as PE without any of the environmental challenges. It can significantly reduce the plastic film use amount in paper packaging

100% Biodegradable

PLA coating is made from cornstarch and sugarcane. It is 100% biodegradable. Compared to the coating of PLA, PE coating is non-biodegradable and almost not able to decompose in landfills and oceans. However, PLA-coated paper can be biodegradable within 6-12 months of composting under specific conditions.

Food Contact Safe

PLA coated paper complies with Bio-standards (EN13432 and ASTM D6400). It can decompose into carbon dioxide and water in a composting environment. It brings non-toxic to the human body and contributes to our environment. Disposable paper container made of PLA coated paper is safe to contact food service under FDA and EU food contact regulation

What Is the PLA Coating Paper Process?

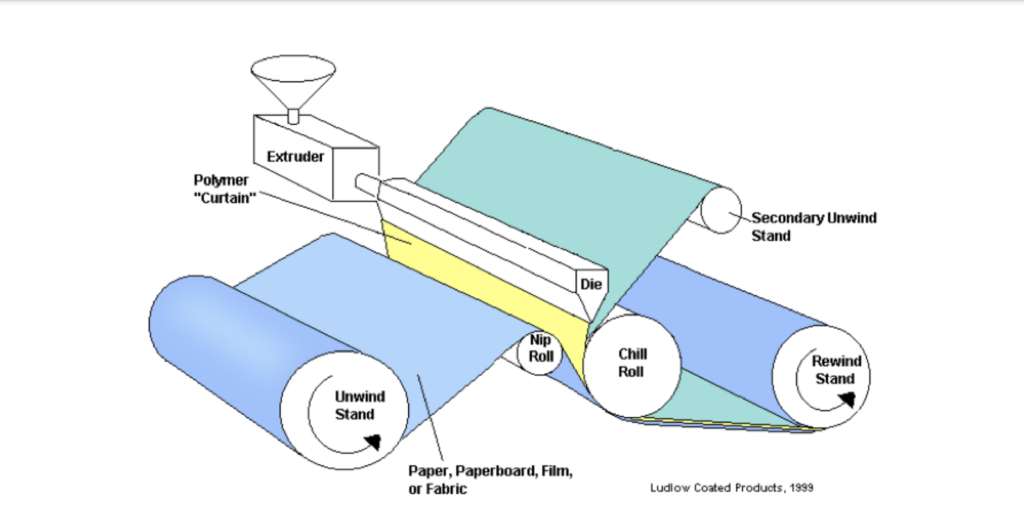

The coating process for PLA waterproof coating is very similar to the PE coating process.the PLA coating process uses a specific technique called extrusion. So first, let’s look at the detailed PLA coating process

Extrusion is when the paper is coated with the polymer to give water-resistant features to the paper. The process of extrusion follows two different techniques, namely extrusion and laminating.

Extrusion: In extrusion, the PLA is melted from its initial form and then fed into a dye that turns it into a sheet. The whole process is done through a machine that features a large screw that pushes the melting plastic through the device into the dye that turns it into a sheet.

Laminating: Laminating involves using a flat dye so that the PLA comes out in the form of a sheet. The sheet is then pressed against the paper to be coated while the film coming out of the dye is still hot. As it is hot, it quickly attaches itself to the paper, and when cooled, a permanent bond is made between the paper and the PLA film. The cooled final product is then rolled into large rolls, which are sent off for the production of anything from a PLA-coated paper cup to other PLA-coated food packaging products.

This is a detailed insight into the process by PLA-coated paper manufacturers to coat various types of paper with PLA film. Other processes, such as PLA dispersion coating, were not discussed here because they are not commonly used.

Now, coming back to the question you may have, what types of papers are used for coating with PLA? Let’s find out.

What Kind of Paper Can Be Coated With PLA?

- PLA Coated Kraft Paper

Kraft paper can be coated with PLA for excellent strength and water resistance. PLA coated kraft paper is ideal for food packaging and sugar sachets. The PLA coating combined with kraft paper makes it one of the most robust paper packaging materials

- PLA Coated White Paper

Contrary to popular belief, white paper is not the same as the paper used in notebooks and books for printing. The food-grade white paper is thick, layered, and meant to be used in packaging only. They are commonly used to make paper cups and bowls with custom logo printing. PLA liner makes it more robust and waterproof, allowing the container to be sturdy and environmentally friendly at the same time

- PLA Coated Bamboo Paper

Bamboo paper is paper pulp made from the bamboo plant. It is the new choice of food packaging material because of its eco-friendly benefit and sustainability.

It is expected that bamboo paper might be used as a replacement for the white and kraft paper since the bamboo paper is more sustainable.

So currently, bamboo paper is also used for making paper cups and other hot and cold beverage cups with PLA coating, making them completely biodegradable and environmentally safe.

What Is PLA Coated Paper Application?

Different Disposable Food containers are the most common uses of PLA coated paper. So, now let’s explore the various benefits of PLA coated paper.

- Paper Cup

PLA coating was the most widely used in paper cups. As a biodegradable alternative to pe coating paper, it makes them stronger and water-resistant. And it also does not affect the taste of the drink in the cup in any way.

So, it was a prevalent choice to pe coat paper for a long time. Today, there are no distinguishable differences between a PLA-coated paper cup and a PE-coated paper cup

- Paper Bowl

Paper bowls are used for serving take-out food. They are also widespread examples that need PLA coated paper. Paper bowls need PLA coating because of biodegradable needs and more muscular paper strength.

Take-out foods typically have wet ingredients in them. The liquid will ultimately go through paper containers without PLA coating. PLA film weight is typically above 30gsm. It strengthens the paper bowl to hold the food in transit without any problems

Paper Food Box(Take-out Container)

Whether for storing sweets or packing food, paper food boxes are trendy and used by restaurants to event caterers for packaging food. These food boxes deal with various foods. And they need to maintain their structural integrity throughout.

PLA coating is used nowadays to provide stability and strength to these food boxes and ensure that the food remains fresh and utterly true to its taste.

- Paper Bag

Take-away the paper bags of other different sizes also need PLA coated paper for the same reasons as the food boxes. PLA coating paper provides sturdiness and protection against all types of take-out food at all temperatures. nowadays to provide stability and strength to these food boxes and ensure that the food remains fresh and utterly true to its taste.

Will PLA Coated Paper Decompose in Nature

Yes, but it still takes a long time. When PLA started to become popular, its environmental benefits had to be taken with a bit of a grain of salt. Why?

Because even though PLA products are biodegradable and can be composted, PLA coating paper containers could not compost in your home.

They required particular industrial composting conditions, which will make PLA-coated paper be heated to a certain degree to activate its biodegradability.

So, since PLA-coated paper products could not be compostable in wild, they had to be transported to particular facilities. This process is the temporal situation for PLA-coated paper. It is not home compostable as of yet.

Understanding PE coating vs. PLA Lining

However, when you compare the eco-benefits of PLA vs. PE, you will see that even though PLA is not perfect and does not allow recycling or home composting, it is still more eco-friendly and has a lower carbon footprint than PE in the long run

- Raw material source

PE coating is petroleum-based polyethylene, mainly obtained from natural gas or petroleum. It is widely used in different plastic bags and plastic containers because it won’t break down in a natural environment for hundreds of years.

PLA is plant-based material known as bio-plastic. It is from renewable resources like corn starch or sugar cane. PLA breaks down shorter time than PE in the environment without any toxic residues

- Heat resistant Feature

Pe coating is hot resistant and can stand up to 120 centigrade. Therefore, it is perfect for hot food and drink.

PLA itself has a lower melt point than pe liner. But PLA coating paper can stand 100 centigrade; it is also okay for hot food.

- Weight of PE and PLA coating

The weight of the film can affect the quality of the paper container. So here is the rule to follow: “The heavier coating paper, the better quality.”

PE coating is usually 15gsm-20gsm for paper for the paper cup and paper bowl. Compared to pe liner, PLA liner is 30gsm. Therefore, it is thicker and more vital.

- Waterproof Feature

PE and PLA Liner can both create a waterproof layer on the paper. They are all good enough to prevent the liquid from leaking from the paper container.

- Recycled way-PE vs. PLA

The PE coating needed to be removed from PE coating paper products before being recycled, which is a hectic task. This process led to most of them being pushed to landfills.

PLA lined will be biodegradable and recyclable in industrial conditions. Besides, PLA is almost zero carbon footprint.

PLA Paper Market: Trend, Opportunities, & Challenges

When you think about biodegradable coating for paper, PLA coating is one of the most popular options. Being sourced from natural sources, it makes PLA coating biodegradable

Trend

The PLA paper market is still evolving, and companies are slowly realizing the benefits of PLA. One of the main reasons movements took this long was because PE was much cheaper than PLA.

However, due to the current rising global PLA production scale, the prices of PLA will be estimated to be low in the future.

Opportunities

For manufacturers, PLA can be used for coating paper on the same infrastructure used with PE. The same infrastructure means no extra facility cost to manufacture PLA lining paper.

Today, PLA products provide better water resistance than PE-coated products.

Studies have shown that by just using industrial-grade white paper with PLA lining, the paper can be more water-resistant and sturdier than PE-coated paper cups. These opportunities will spearhead the industry forward and toward a greener future for humanity as a whole.

Challenges

The only challenge in the way right now is awareness. When you go for your cup of coffee in the morning, you don’t probably stop to think if your paper cup is lined with PE or PLA. It is about consumer habit shifts and increases in demand for the industry.

Only With increased awareness are these changes quite possible to be made.

Many paper container companies have given in to customer requests and finally developed PLA lined paper products to replace their PE lined series products.

Conclusion

PLA coating paper does provide the expected good results in delivering a greener World. If you are willing to change your habits and ask for PLA-coated products, you can significantly change today’s landscape.

You have the tools needed to make the world greener and a better place for tomorrow; the only question is, are you going to use them?

If

Related content

Full Guide to the Types of Paper Bags(2023)

Full Guide to the Types of Paper Bags(2023) With its biodegradable and eco-friendly characteristics, paper bags contribute to the sustainability of the environment. Today we

17 Best Types of Eco-Friendly food packaging in 2023

17 Best Types of Eco-Friendly food packaging in 2023 Today, I will dive into the fascinating world of eco-friendly food packaging. As sustainability and environmental

The Ultimate Guide To types of ice cream packaging (2023)

The Ultimate Guide To types of ice cream packaging (2023) Ready to dive into the sweet world of ice cream packaging? Today, In this guide,

Can You Recycle Ice Cream Cartons?

Can You Recycle Ice Cream Cartons? In this article, I will share valuable information about ice cream carton recycling, including common types of materials used

The Ultimate Guide To Food Delivery Packaging in 2023

The Ultimate Guide To Food Delivery Packaging in 2023 Today I will show you everything you need to know about food delivery packaging. In this

Best Disposable Bowl for Hot Soup:All You Need To Know (2023 Update)

Best Disposable Bowl for Hot Soup:All You Need To Know (2023 Update) What is the best disposable bowl for hot soup? In this article, you

13 Responses

We are interested to change our PE cups to PLA, please send the detailed quotation.

Hi Sanal we already contact your team

We are interested to change our PE cups to PLA, please send the detailed quotation

Great,we will call our sales to contact you

May i know do you have emulsion of PLA for coting on various substrate.

What are the cost difference between styrofoam and PLA coated paper for food serving?

PlA coated paper is much expensive than styrofoam

Hi, we are looking to procure PLA coating to manufacture cups for our customers

Our team will contact you soon

Everything is very open with a precise clarification of the issues. It was definitely informative. Your site is useful. Thank you for sharing!

In the world of packaging, Biodegradable Containers from India are a breath of fresh air. They are made precisely to decompose organically over time and return to the land without leaving behind any damaging leftovers.

am allergic to sulphites

are there sulphites in pla lined paper cups or bowl

contact us